isimiso sokusebenza

Lapho isihlungi esine-laminated sisebenza ngokujwayelekile, amanzi ageleza ngesihlungi esine-laminated, esebenzisa udonga kanye nomsele ukuze aqoqe futhi avimbe imfucumfucu. Ingxenye engaphakathi eyinhlanganisela ye-groove inikeza ukuhlunga okunezinhlangothi ezintathu okufana nalokho okukhiqizwa esihlabathini nezihlungi zamatshe. Ngakho-ke, ukusebenza kahle kokuhlunga kwayo kuphezulu kakhulu. Uma isihlungi se-laminated sisebenza kahle, isihlungi se-laminated siyakhiyiwa. Isihlungi naso siyagudluka noma sishaywe ngokuzenzakalelayo. Uma kudingeka ukugeza ngesandla, susa isici sokuhlunga, ukhulule i-nati yokucindezela, bese ugeza ngamanzi. Ngesikhathi esifanayo, kunamandla kunokugcinwa kwesihlungi senetha sokungcola, ngakho-ke inani lokugeza lincane kakhulu, ukusetshenziswa kwamanzi okugeza kuncane. Nokho, ishidi laminated kumele libe likhululekile lodwa lapho liwashwa ngokuzenzakalelayo. Ngenxa yethonya lezinto eziphilayo kanye nokungcola kwamakhemikhali emzimbeni wamanzi, amanye amashidi elaminethiwe avame ukunamathela ndawonye futhi akulula ukuwageza kahle.

Inqubo Yokusebenza

Lapho isihlungi esine-laminated sisebenza ngokujwayelekile, amanzi ageleza ngesihlungi esine-laminated, esebenzisa udonga kanye nomsele ukuze aqoqe futhi avimbe imfucumfucu. Ingxenye engaphakathi eyinhlanganisela ye-groove inikeza ukuhlunga okunezinhlangothi ezintathu okufana nalokho okukhiqizwa esihlabathini nezihlungi zamatshe. Ngakho-ke, ukusebenza kahle kokuhlunga kwayo kuphezulu kakhulu. Uma isihlungi se-laminated sisebenza kahle, isihlungi se-laminated siyakhiyiwa. Isihlungi naso siyagudluka noma sishaywe ngokuzenzakalelayo. Uma kudingeka ukugeza ngesandla, susa isici sokuhlunga, ukhulule i-nati yokucindezela, bese ugeza ngamanzi. Ngesikhathi esifanayo, kunamandla kunokugcinwa kwesihlungi senetha sokungcola, ngakho-ke inani lokugeza lincane kakhulu, ukusetshenziswa kwamanzi okugeza kuncane. Nokho, ishidi laminated kumele libe likhululekile lodwa lapho liwashwa ngokuzenzakalelayo. Ngenxa yethonya lezinto eziphilayo kanye nokungcola kwamakhemikhali emzimbeni wamanzi, amanye amashidi elaminethiwe avame ukunamathela ndawonye futhi akulula ukuwageza kahle.

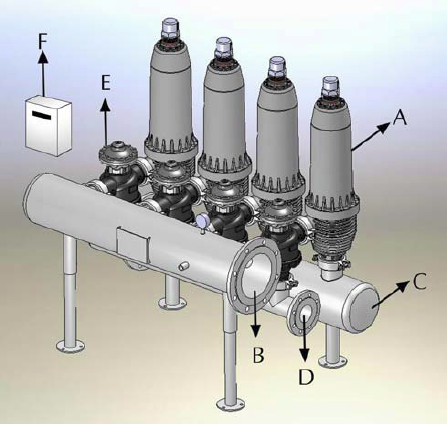

Ukuhlunga

Amanzi ageleza nge-inlet yokuhlunga esihlungi, isitaki sokuhlunga sicindezelwa ngokuqinile ndawonye ngesitaki sokuhlunga ngaphansi kwesenzo samandla entwasahlobo namandla we-hydraulic, izinhlayiya zokungcola ziyabanjwa endaweni yokuwela isitaki, amanzi ahlungiwe aphuma esiteshini esikhulu sesihlungi, ngalesi sikhathi i-valve ye-diaphragm yendlela eyodwa ivuliwe.

Ukugeza ngemuva

Lapho umehluko othile wengcindezi ufinyelelwa, noma isikhathi esimisiwe, uhlelo lungena ngokuzenzakalelayo endaweni yokuwasha i-backwash, isilawuli silawula i-valve ukushintsha isiqondiso sokugeleza kwamanzi, i-diaphragm yendlela eyodwa engezansi kwesihlungi ivala umzila omkhulu, i-backwash ingena emaqenjini amane wesiteshi se-nozzle, kanye nesiteshi somlomo esixhunywe negumbi le-piston lokucindezela kwamanzi kuyakhuphuka, ukucindezela kwe-piston kunqobe isikhala bese kunqoba isikhala. phezulu kwesitaki. Ngesikhathi esifanayo, amanzi okugeza emuva afafazwa ngesivinini esikhulu kusuka ku-35 * 4 nozzles ngaphezu kwamaqembu amane eziteshi ze-nozzle eduze komugqa we-tangent we-stack, ukuze isitaki sijikeleze futhi sihlukaniswe ngokulinganayo. Amanzi okugeza afuthwa ukuze kugezwe ingaphezulu lesitaki, futhi ukungcola okungene esitakini kuyafuthwa bese kulahlwa ngaphandle. Uma i-backwash iqedile, isiqondiso sokugeleza sishintsha futhi, i-laminate iphinda icindezelwe, futhi uhlelo luphinde lungene esimweni sokuhlunga.

Ipharamitha Yezobuchwepheshe

| Izinto zegobolondo | ipayipi lensimbi lepulasitiki elifakwe ulayini |

| Hlunga izindlu zekhanda | inayiloni eqinisiwe |

| Izinto ezenziwe nge-laminated | I-PE |

| Indawo yokuhlunga (i-laminated) | 0.204 square metres |

| Ukunemba kokuhlunga (um) | 5, 20, 50, 80, 100, 120, 150, 200 |

| Ubukhulu (ubude nobubanzi) | 320mmX790mm |

| Ingcindezi yokusebenza | 0.2MPa -- 1.0MPa |

| Ukucindezela kwe-backwash | ≥0.15MPa |

| Izinga lokugeleza kwe-backwash | 8-18m/h |

| Isikhathi sokugeza emuva | 7 -- 20S |

| Ukusetshenziswa kwamanzi okugeza ngemuva | 0.5% |

| Izinga lokushisa lamanzi | ≤60℃ |

| Isisindo | 9.8kg |

Izinzuzo zomkhiqizo

I-1.I-filtration eqondile: Amapuleti okuhlunga anokunemba okuhlukile angakhethwa ngokuya ngezidingo zamanzi, kufaka phakathi i-20 micron, i-55 micron, i-micron engu-100, i-micron engu-130, i-micron engu-200, i-micron engu-400 nezinye izincazelo, futhi isilinganiso sokuhlunga sikhulu kune-85%.

2. I-backwashing ejulile futhi ephumelelayo: Ngenxa yokuthi izimbotshana zokuhlunga zivuleka ngokuphelele ngesikhathi sokuwashwa ngemuva, kuhlanganiswe nomjovo we-centrifugal, umphumela wokuhlanza awukwazi ukufezwa ezinye izihlungi. Inqubo yokuwasha ngemuva ithatha kuphela imizuzwana eyi-10 ukuya kwengama-20 ngeyunithi yesihlungi ngasinye.

3.Ukusebenza okuzenzakalelayo okugcwele, ukukhishwa kwamanzi okuqhubekayo: isikhathi nokucindezela umehluko wokulawula ukuqala kwe-backwash. Kusistimu yokuhlunga, iyunithi yokuhlunga ngayinye nezindawo zokusebenza ziwashwa ngemuva ngokulandelana. Ukushintsha okuzenzakalelayo phakathi kwezimo zokusebenza nokuwashwa ngemuva kungaqinisekisa ukuphuma kwamanzi okuqhubekayo, ukulahlekelwa kwengcindezi ephansi yesistimu, kanye nomphumela wokuhlunga nokuwashwa ngemuva ngeke wonakaliswe ngenxa yesikhathi sokusetshenziswa.

I-4.Umklamo we-Modular: Abasebenzisi bangakhetha inani lamayunithi okuhlunga afanayo ngokusho kwesidingo, ukuguquguquka nokuguquguquka, ukushintshashintsha okunamandla. Ukusetshenziswa okuguquguqukayo kwesikhala sekhona lesayithi, ngokuya ngezimo zendawo indawo yokufaka encane.

I-5.Ukugcinwa okulula: cishe asikho isidingo sokugcinwa kwansuku zonke, ukuhlolwa namathuluzi akhethekile, izingxenye ezimbalwa ezitholakalayo. Isici sesihlungi se-laminated ayidingi ukushintshwa, futhi impilo yesevisi ingaba yiminyaka eyi-10.

Inkambu yohlelo lokusebenza

I-1.Isihlungi esigcwele noma isihlungi esiseceleni samanzi ajikelezayo wombhoshongo wokupholisa: singaxazulula ngokuphumelelayo inkinga yokuvinjelwa kwamanzi okujikelezayo, ukunciphisa ukusetshenziswa kwamandla, nokunciphisa umthamo, ukuvimbela ukwehluleka nokuvala futhi kunciphise izindleko zokugcinwa kwesistimu.

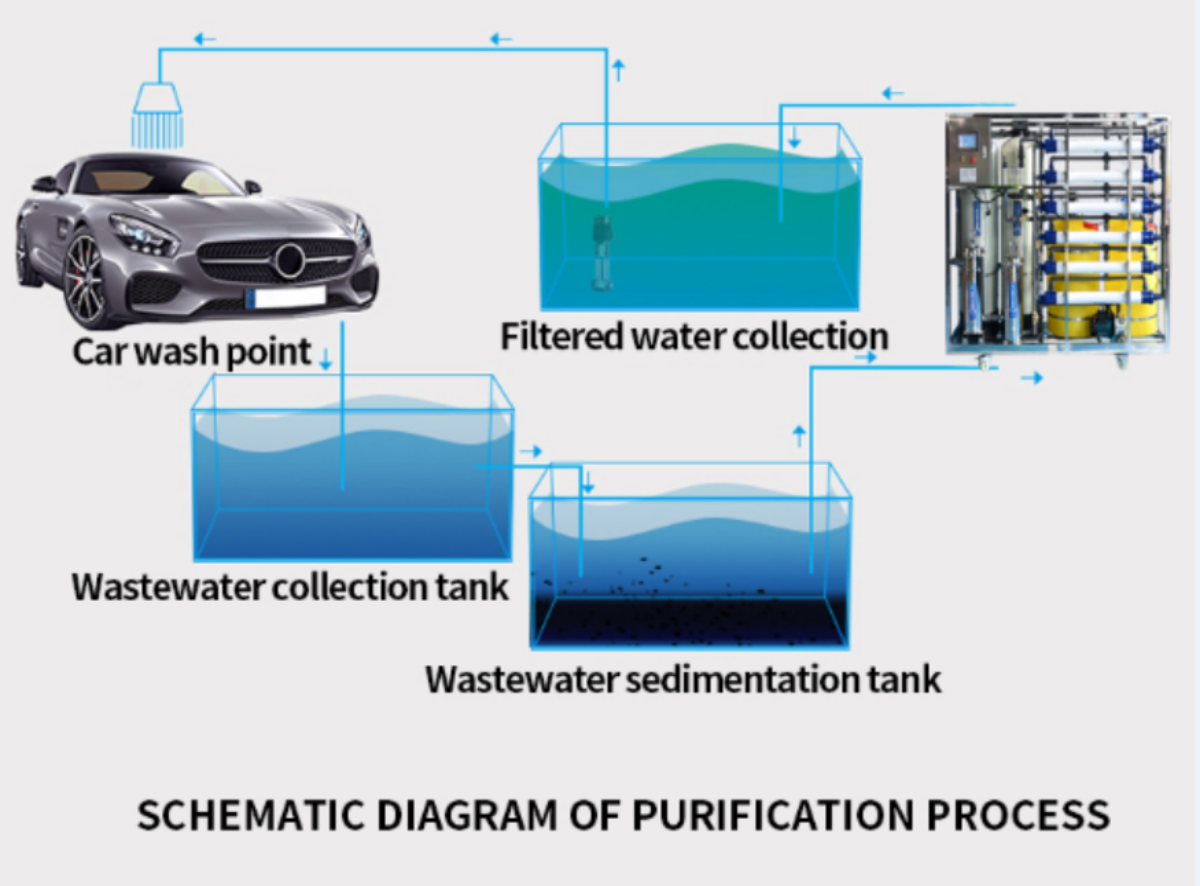

2. Ukuphinda kusetshenziswe amanzi abuyiselwe kanye nokulungiswa kwendle: yonga inani eliphelele lamanzi, uthuthukise izinga lamanzi asetshenzisiwe, unciphise noma ugweme ukungcola okubangelwa ukuthululwa kwendle okuqondile endaweni ezungezile.

3.Ukwelashwa kokukhipha usawoti emanzini olwandle: susa ukungcola kanye nama-microorganisms asolwandle emanzini olwandle. Ukumelana nosawoti kanye nokumelana nokugqwala kwesisefo sepulasitiki kungcono kunokwezinye izisetshenziswa ezibiza kakhulu zokuhlunga ingxubevange yensimbi.

4.Ukuhlunga okuyinhloko ngaphambi kokuhlunga kwe-ultrafiltration kanye nokwelashwa kwe-osmosis ulwelwesi oluhlehlisayo: ukuvikela isici sokuhlunga ukunemba nokwelula impilo yaso yesevisi.

Ngaphandle kwalokho, izihlungi ezinamalayini zisetshenziswa kabanzi ku: imboni yamakhemikhali, amandla kagesi, insimbi, ukukhiqizwa kwemishini, ukucubungula ukudla nesiphuzo, amapulasitiki, amaphepha, izimayini, i-metallurgy, izindwangu, i-petrochemical, imvelo, igalofu, imoto, isihlungi sangaphambili samanzi kampompi.